When people think about truck drivetrain components, transmissions and differentials often take center stage. But for many heavy-duty truck drivelines, especially those in vocational and off-highway applications, there’s another critical piece of the puzzle: the transfer case. This underappreciated unit is responsible for distributing power where it’s needed most, ensuring trucks can handle the toughest terrain, heaviest loads, and most demanding work environments.

In this article, we’ll explore what transfer cases do, why they matter, common reasons they fail, and the advantages of choosing a remanufactured transfer case from an experienced supplier.

What Does a Transfer Case Do?

A transfer case is a gearbox that takes power from the transmission and directs it to multiple drive axles. In most setups, it splits torque between the front and rear axles, allowing a truck to achieve true all-wheel or four-wheel drive capability.

For heavy-duty trucks and specialized equipment, transfer cases do much more than just distribute torque:

- Power distribution: Essential for tandem axle trucks, vocational vehicles, and off-highway machinery that demand equalized traction.

- Gear reduction: Many transfer cases include low-range gearing, giving trucks the torque boost needed for steep grades, soft ground, or heavy pulls.

- Versatility: With shifting options (manual, air, or electronic), drivers can engage or disengage front axles on demand, saving fuel and wear on driveline components.

Transfer Case Designs in Heavy-Duty Applications

Not all transfer cases are created equal. In fact, the variety of designs reflects the wide range of industries they serve.

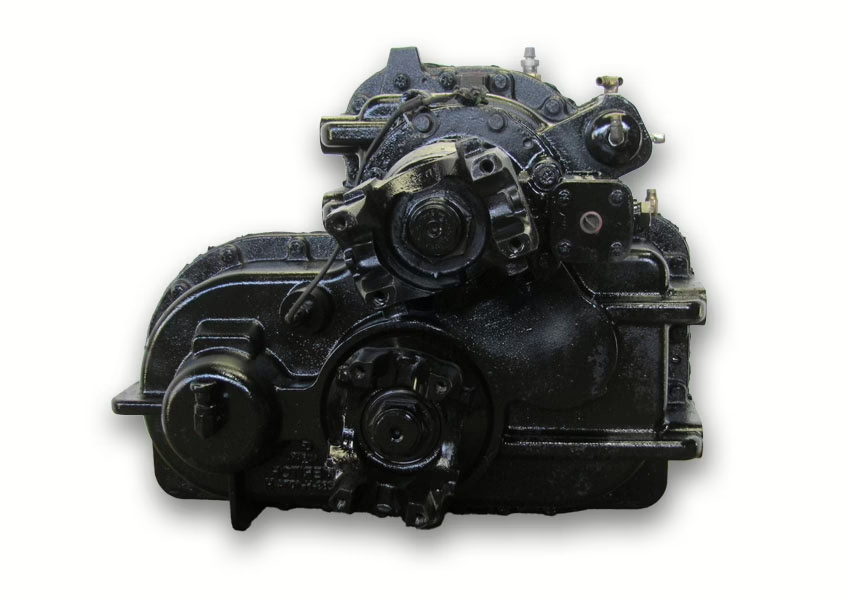

1. Gear-Driven Transfer Cases

- Built for maximum strength and often found in severe-service trucks and heavy equipment.

- Utilize heavy-duty gears rather than chains, making them ideal for continuous operation under load.

2. Chain-Driven Transfer Cases

- Common in lighter vocational trucks and some on-highway units.

- Quieter and lighter in weight than gear-driven, but may not handle extreme torque as well.

3. Shift Control Options

4. Off-Highway Specializations

In mining, construction, and forestry, off-highway trucks depend on rugged transfer cases that can survive constant exposure to dust, mud, water, and extreme torque demands. These environments often dictate gear-driven designs with reinforced housings and extra cooling capabilities.

Why Transfer Cases Fail

Despite their rugged construction, transfer cases are not invincible. Over time, stress, wear, and improper maintenance can lead to failure. The most common causes include:

- Lubrication issues: Running with low, contaminated, or incorrect fluid leads to overheating and bearing or gear failure.

- Seal wear: Leaking seals allow fluid loss and contamination.

- Overloading: Pushing the drivetrain beyond its torque capacity accelerates wear.

- Improper installation: Misalignment or incorrect torque specs can reduce service life.

- Neglected maintenance: Skipping fluid changes or ignoring unusual noises often results in costly damage.

When a transfer case fails, the truck is out of service — and downtime is costly for fleets and operators alike.

The Case for a Remanufactured Transfer Case

When faced with a failing transfer case, owners typically weigh three options: buy new, buy used, or buy remanufactured. Here’s why choosing a remanufactured transfer case is often the smartest choice:

1. Cost Savings

- A remanufactured unit is significantly less expensive than new, while offering comparable performance.

- Pricing typically falls between “used” and “new,” but with far more reliability than a used component.

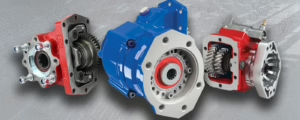

2. OEM Specifications Restored

- A quality remanufacturer disassembles the transfer case, inspects every component, and replaces all wear items (bearings, seals, gaskets, and often gears).

- Critical parts are machined or replaced to ensure like-new tolerances.

3. Quality Control

- Many remanufacturers dyno test their transfer cases, simulating real-world torque loads and ensuring proper function before shipment.

- This level of testing gives peace of mind that the unit will perform reliably in the field.

4. Availability of Hard-to-Find Units

- For older models or discontinued part numbers, remanufactured transfer cases may be the only option.

- Trusted suppliers often maintain extensive inventories of these hard-to-source driveline components.

5. Environmental Responsibility

- Remanufacturing saves energy and resources by reusing housings and hard parts, reducing the need for raw materials.

Transfer Cases in Off-Highway Applications

For fleets working in off-highway environments — construction sites, logging roads, oilfields, mines — transfer cases are subjected to the harshest conditions.

A heavy-duty truck driveline in these environments relies on:

- Continuous torque delivery to multiple axles.

- Durable gear reduction for extreme loads at low speeds.

- Resistance to contaminants, from abrasive dust to water and mud.

A remanufactured transfer case built and tested to OEM standards ensures the truck can keep working even in these unforgiving environments. For operators, that means fewer breakdowns, lower maintenance costs, and better productivity.

How to Choose the Right Transfer Case

When sourcing a replacement or upgrade, consider:

- Transmission compatibility: PTO drives and gear ratios must match the transmission model.

- Axle configuration: Tandem axles, steerable lift axles, and all-wheel drive require different torque splits.

- Application: Vocational fleets like dump trucks, mixers, and refuse vehicles may need different options than over-the-road haulers.

- Supplier expertise: Work with a supplier that has decades of experience in the heavy-duty truck driveline industry and can provide both product and technical support.

General Truck Parts: Your Source for Remanufactured Transfer Cases

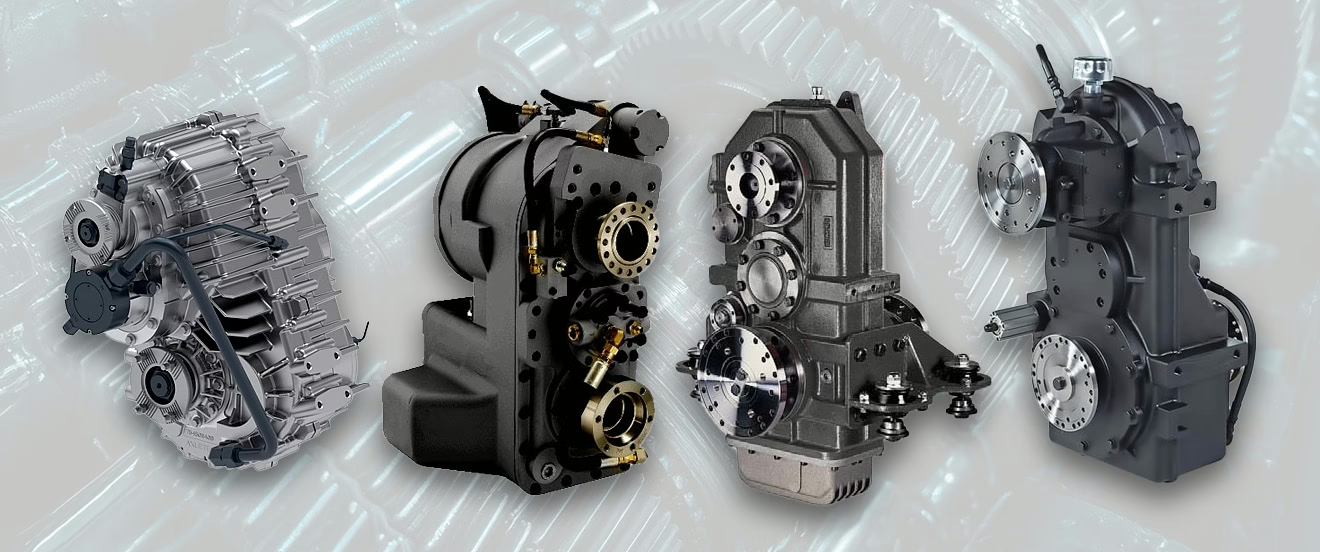

At General Truck Parts, we’ve spent over 50 years remanufacturing and supplying critical drivetrain components. Our inventory includes:

- Remanufactured transfer cases for a wide range of heavy-duty and off-highway trucks.

- Manual, automated manual, and automatic transmissions.

- Differentials, PTOs, axles, and related driveline parts.

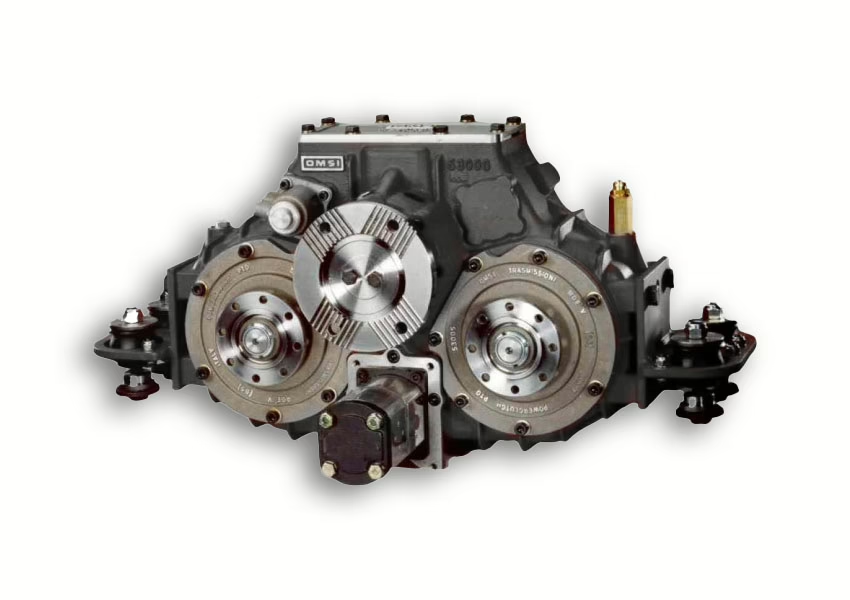

Every remanufactured unit is built to OEM specifications, tested for performance, and backed by warranty. With one of the largest inventories of hard-to-find components in the industry by trusted brands like AxleTech, Cotta, Eaton/Fuller, Fabco, Meritor, OMSI and Dana/Spicer, we’re committed to keeping your trucks on the road.

Transfer Cases FAQs

Q1: What is the purpose of a transfer case in a heavy-duty truck driveline?

A transfer case distributes engine power from the transmission to multiple axles. In heavy-duty and off-highway trucks, it ensures proper torque delivery for traction, load handling, and low-speed operations.

Q2: Why should I choose a remanufactured transfer case instead of a new one?

A remanufactured transfer case provides OEM-level performance at a lower cost. It’s rebuilt with new bearings, seals, and critical parts, tested for reliability, and often comes with a warranty—making it more dependable than used units and more affordable than new ones.

Q3: How often should transfer case fluid be changed in a work truck?

Maintenance intervals vary by manufacturer and application, but many heavy-duty truck drivelines require fluid inspection every 25,000–30,000 miles and replacement between 50,000–100,000 miles. Off-highway trucks working in harsh conditions may need more frequent service.

Q4: Can transfer cases be rebuilt if parts are no longer available?

Yes, in many cases. Experienced remanufacturers like General Truck Parts maintain extensive inventories of hard-to-find parts, allowing them to rebuild even discontinued or obsolete transfer cases to OEM specifications.

Transfer cases may not get the same recognition as transmissions or differentials, but in the world of heavy-duty truck drivelines, they are essential. From distributing power to multiple axles to delivering low-range torque in off-highway applications, transfer cases keep work trucks moving when it matters most.

When it comes time for service or replacement, a remanufactured transfer case offers the best combination of performance, availability, cost savings, and sustainability. Contact us today to partner with an experienced remanufacturer like General Truck Parts to ensure your driveline components deliver the reliability your vehicle depends on.

Recent Knowledge Base Articles

Contact Us Today

Our Experts are available to answer your questions and help you with your needs.

We take pride in getting you your answers, parts, and assemblies fast.

| 800-621-3914 |