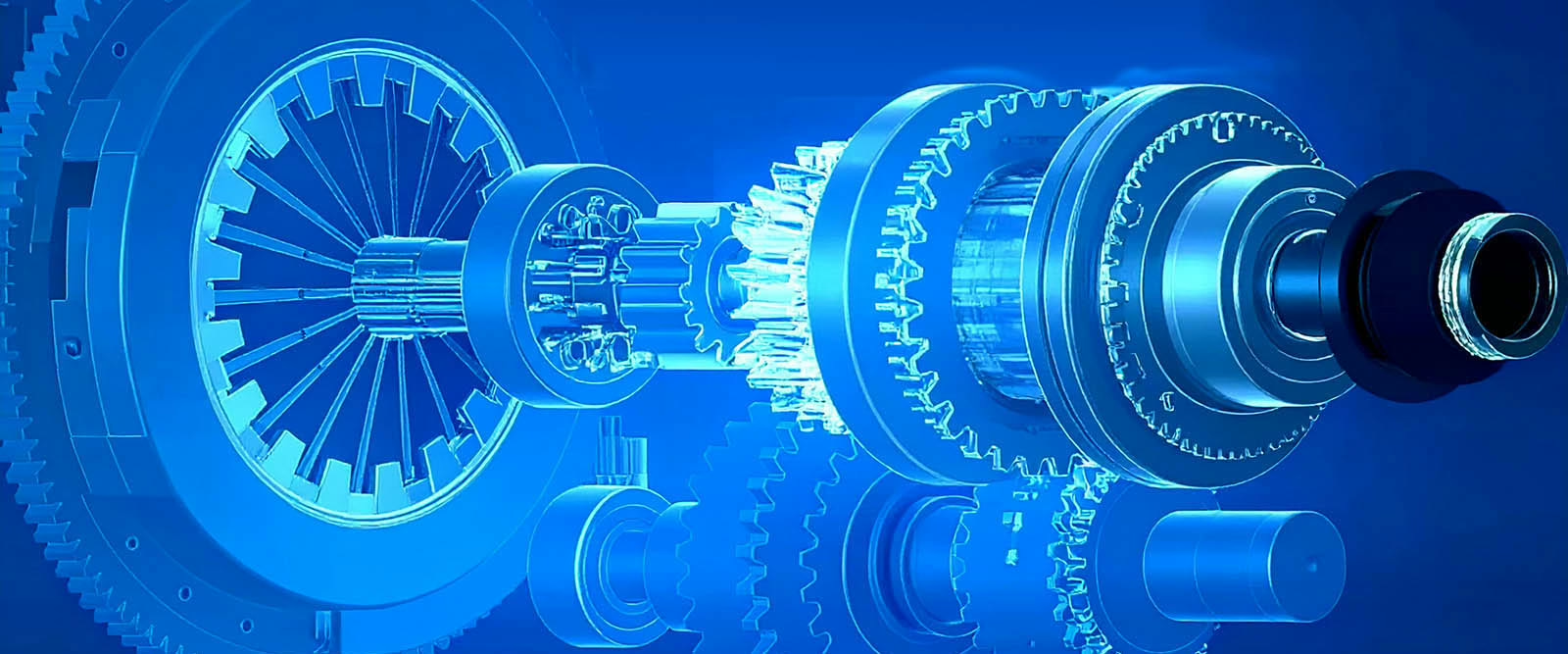

The clutch and transmission are two of the most critical components in a heavy-duty truck’s driveline. Together, they manage the delivery of power from the engine to the driveshaft, converting combustion energy into usable torque that moves tens of thousands of pounds down the highway.

Understanding how these systems interact—and how their design changes between manual, automated manual, and automatic transmissions—is key to diagnosing problems, performing maintenance, and choosing the right components for your application.

The Power Path: How the Clutch and Transmission Work Together

At its simplest, the clutch is the mechanical link between the engine and the transmission. The engine crankshaft is always spinning when the truck is running, but the transmission and wheels must occasionally stop or change speeds. The clutch allows that connection to be engaged or disengaged smoothly, controlling when engine torque is transmitted to the driveline.

When the clutch is engaged, torque flows from:

- Engine flywheel →

- Clutch assembly (friction discs, pressure plate, release system) →

- Transmission input shaft →

- Transmission gear sets →

- Output shaft and driveline

When the clutch is disengaged, this flow of torque is interrupted, allowing the transmission to shift gears without grinding or damaging components.

The Clutch Assembly: Components and Function

A heavy-duty truck clutch is designed to withstand high torque loads, heat, and continuous duty cycles. It’s typically larger and more robust than light-duty automotive clutches and often uses two friction discs (a twin-plate design) for increased torque capacity.

Main Components:

- Flywheel – Bolted to the engine crankshaft, it provides a friction surface and rotational mass to stabilize engine speed.

- Clutch Discs (Driven Plates) – Lined with friction material, these discs are splined to the transmission input shaft. They transfer torque when clamped between the flywheel and pressure plate.

- Pressure Plate Assembly – Applies clamping force against the clutch discs via heavy-duty coil or diaphragm springs.

- Release Bearing (Throwout Bearing) – Engages the pressure plate levers to disengage the clutch when the pedal (or actuator) is depressed.

- Clutch Brake – A unique feature in heavy-duty manual systems; it stops the transmission input shaft from spinning, allowing gear engagement at a standstill.

- Release Mechanism – Can be mechanical linkage, hydraulic, or pneumatic, depending on the system.

The clutch’s role is momentary but essential—it provides a controlled connection between the continuously spinning engine and the selectively geared transmission.

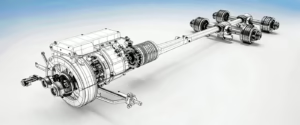

The Transmission: How It Uses the Clutch’s Input

The transmission takes the rotating torque from the clutch and converts it into various gear ratios. Each gear ratio multiplies torque and adjusts output speed to suit different operating conditions (starting from a stop, climbing grades, cruising at highway speed, etc.).

A heavy-duty truck transmission generally includes:

- Input Shaft – Receives torque from the clutch.

- Countershaft(s) – Transfer power from the input shaft to the mainshaft through meshed gears.

- Mainshaft – Transmits power to the output shaft and driveline.

- Gear Sets – Provide the range of speed and torque ratios.

- Synchronizers or Sliding Clutches – Allow gears to engage smoothly in some designs.

- Shift Forks and Rails – Mechanically or electronically move gears in and out of engagement.

- Lubrication System – Circulates oil to reduce friction and wear.

How the clutch interacts with the transmission—and how much driver involvement is required—varies widely between manual, automated manual, and automatic drivetrains.

Manual Transmissions: Direct Driver Control

In a manual transmission, the clutch pedal and shift lever are both directly controlled by the driver.

- The driver depresses the clutch pedal, disengaging the clutch.

- The shift lever moves internal shift forks, engaging a new gear.

- The clutch is then re-engaged to reconnect the engine to the driveline.

Key Features:

- Full driver control over engine speed and gear selection.

- Clutch brake enables smooth gear selection from a standstill.

- Common configurations include 9-, 10-, 13-, 15-, and 18-speed transmissions (such as Eaton Fuller RTLO series).

- Double clutching may be needed for non-synchronized gearboxes.

Manual systems are durable and cost-effective but require skilled drivers and regular clutch maintenance. The clutch experiences more wear since engagement control is manual.

Automated Manual Transmissions (AMTs): Computer-Controlled Precision

An Automated Manual Transmission (AMT) combines the mechanical architecture of a manual transmission with the automation of clutch and gear selection through electronic controls.

Key Differences:

- The clutch is actuated by electro-hydraulic or electro-pneumatic servos, not a pedal.

- The Transmission Control Unit (TCU) coordinates engine speed, clutch engagement, and gear shifting.

- Drivers typically select drive modes (Drive, Neutral, Reverse), while the system handles shifting logic.

Operation:

- The TCU reads data from sensors (engine speed, vehicle speed, load).

- It commands clutch disengagement and selects the appropriate gear.

- It modulates clutch re-engagement for smooth power delivery.

Advantages:

- Improved fuel efficiency through optimal shift timing.

- Reduced driver fatigue.

- Consistent clutch wear and longer component life due to precise actuation.

- Easier training for new drivers.

AMTs retain a traditional clutch assembly and mechanical gearbox, but the human element is replaced by automation—allowing heavy-duty torque handling with the efficiency of computerized control.

Fully Automatic Transmissions: Torque Converter Systems

In contrast, a fully automatic transmission (common in vocational and municipal trucks) uses a torque converter instead of a traditional clutch.

Torque Converter Components:

- Pump (Impeller) – Driven by the engine; pushes transmission fluid.

- Turbine – Connected to the transmission input shaft; receives fluid energy from the pump.

- Stator – Redirects fluid between the turbine and pump for torque multiplication.

- Lockup Clutch – Engages at higher speeds for direct mechanical connection and efficiency.

Key Characteristics:

- No clutch pedal—the fluid coupling allows the engine to idle while the truck is stationary.

- Planetary gearsets and hydraulic control valves automatically change gear ratios.

- Modern automatics (e.g., Allison 4000 series) use electronic controls for shift timing and torque management.

Advantages:

- Seamless power delivery and no shift shock.

- Ideal for stop-and-go or off-road duty cycles.

- Minimal driver input and reduced driveline shock loads.

However, automatic systems are generally heavier and more complex, and their torque converters generate more heat compared to the mechanical coupling of a clutch.

Comparison Summary

| Feature | Manual Transmission | Automated Manual | Fully Automatic |

| Clutch Type | Twin-plate mechanical | Twin-plate, electronically actuated | Torque converter |

| Shift Control | Manual (driver-operated) | Computer-controlled | Hydraulic/electronic automatic |

| Driver Involvement | High | Low | Minimal |

| Efficiency | High (skilled driver) | Very high (optimal shifts) | Moderate |

| Maintenance | Clutch adjustments, linkage | Software calibration, clutch wear | Fluid and filter service |

| Best For | Linehaul, skilled operators | Long-haul fleets, fuel efficiency | Stop-and-go, vocational trucks |

Why Understanding This Relationship Matters

Knowing how the clutch and transmission interact helps technicians and fleet managers:

- Diagnose driveline issues such as clutch slippage, hard shifting, or gear grinding.

- Select the right replacement components—such as compatible clutch assemblies, input shafts, or synchronizers.

- Optimize maintenance schedules for clutch adjustments, transmission oil changes, and software updates.

- Improve uptime and drivability, reducing total cost of ownership.

At General Truck Parts, we stock a full range of clutch assemblies, flywheels, transmission components, and complete reman transmissions from trusted OEMs like Dana, Spicer, Meritor, Fabco, and Eaton. Whether your fleet runs manual, AMT, or automatic transmissions, we can help you keep your powertrain performing at its best. Contact us today to get started.

Recent Knowledge Base Articles

Contact Us Today

Our Experts are available to answer your questions and help you with your needs.

We take pride in getting you your answers, parts, and assemblies fast.

| 800-621-3914 |