Automated Manual Transmissions (AMTs) are hybrid gearboxes that combine the internal mechanism of a traditional manual transmission with electronic controls to automate clutch engagement and gear shifting. In essence, an AMT uses a standard manual gearbox (with its multiple gear sets and clutches) but relieves the driver of having to operate the clutch pedal or shift lever. Instead, computer-controlled actuators handle all clutch and shift actions, giving the ease of an automatic while retaining the efficiency and robustness of a manual. This technology has become increasingly dominant in heavy-duty trucks, bridging the gap between fully manual gearboxes and conventional torque-converter automatics. By the 2020s, the vast majority of new Class 8 trucks are being sold with AMTs instead of manual transmissions, marking a transformative shift in an industry that once relied almost exclusively on driver-shifted gears.

Origins and Evolution of AMTs in Heavy-Duty Trucks

For decades, heavy trucks were built with either manual transmissions (requiring driver skill to master multi-speed gearboxes) or automatic transmissions (using torque converters, mostly in vocational roles). Manuals long dominated long-haul tractors due to their direct mechanical efficiency and driver preference for control. Automatics (like the Allison torque-converter transmissions) were valued in certain applications for their smooth power delivery, but they carried higher cost and weight. Around the late 1990s and early 2000s, a new option emerged: the Automated Manual Transmission. Early prototypes of heavy-truck AMTs were essentially modified manual gearboxes with add-on electronics to assist shifting. For example, Eaton and Rockwell (Meritor) both experimented with semi-automated manual systems in the 1990s – Eaton’s early “AutoShift” systems and Meritor’s “Top 2” or FreedomLine gearboxes – but initial adoption was limited. These first-generation systems often required the driver to use a clutch when starting or stopping (so-called three-pedal systems) and then automated the gear changes once underway. They demonstrated the concept’s promise, but fleets and drivers were initially cautious.

The turning point for AMTs came in the early 2000s. In Europe, Volvo Trucks introduced its revolutionary I-Shift transmission in 2001, which is often cited as the world’s first production heavy-duty AMT. This was a bold move – an entirely two-pedal, clutch-by-wire system in high-horsepower trucks – and it was met with skepticism by an industry steeped in manual-shifting tradition. Critics questioned if an automated gearbox could be as durable or reliable as a manual. Volvo persisted with extensive testing, and the I-Shift quickly proved its value by lowering fuel consumption, improving safety, and reducing driver fatigue compared to manuals. It turned out to be a game-changer: “a major game changer soon became a major success,” as Volvo’s transmission manager reflected years later. By 2007, Volvo brought the I-Shift to North America, and it steadily gained acceptance in fleets. In fact, Volvo made the I-Shift standard on all its highway trucks by 2013, and as of 2021 Volvo had sold over 1 million I-Shift units globally. In North America alone, more than 217,000 Volvo trucks were running I-Shifts by 2021, and over 94% of Volvo’s new trucks were ordered with AMTs instead of manuals – a remarkable shift in a market once dominated by stick-shifts.

Other manufacturers were following a similar trajectory. Eaton Corporation, long known for its Fuller manual transmissions, launched its first true two-pedal AMT in the mid-2000s. In 2006 Eaton introduced the UltraShift transmission, eliminating the clutch pedal and fully automating gear changes (building on its earlier AutoShift which still had a clutch pedal for starting). Around the same time, Volvo’s North American division was rolling out the I-Shift domestically, and Mack Trucks (a Volvo subsidiary) adapted the I-Shift into the Mack mDrive by 2010. In Europe, ZF introduced its AS-Tronic AMT in 2003 which was adopted by brands like DAF and Iveco, and Renault (also part of the Volvo Group) launched its Optidriver AMT in 2004.

In North America, Meritor (formerly Rockwell) partnered with ZF to offer the FreedomLine AMT in the early 2000s. Meritor was so confident in this fully-automated 12-speed gearbox that by 2006 it decided to stop manufacturing manual transmissions altogether and focus on AMTs, touting FreedomLine’s advanced technology. This was a bold bet that mirrored the industry’s direction – Meritor believed fleets would increasingly prefer automated shifting. Indeed, by the early 2010s, the major truck OEMs all had their “own” AMTs either developed in-house or through partnerships.

Daimler Trucks North America (DTNA) – manufacturer of Freightliner and Western Star – entered the AMT arena with the Detroit DT12 around 2012. The DT12 (named after Daimler’s Detroit Diesel brand) was introduced on Freightliner’s flagship Cascadia model and was part of Daimler’s global strategy to integrate engines, transmissions, and axles for maximum efficiency. (The DT12 is based on a Mercedes-Benz gearbox used in Europe, adapted for the North American market.) Production of the DT12 began in 2013-2014, initially built in Germany and then moved to Detroit’s US facilities by 2015. Like its competitors, the DT12 quickly gained favor among fleets for its fuel efficiency and ease of use.

By the late 2010s, AMTs had matured and achieved mainstream acceptance. Truck makers saw rapid uptake as fleets large and small recognized the benefits. For example, at Daimler, the AMT installation rate in new highway trucks jumped from ~15% in 2012 to over 90% by the late 2010s. Volvo Trucks saw North American AMT adoption climb from single-digit percentages in 2007 to 95% by 2021. Freightliner’s experience was similar: by 2017 about 70% of all Freightliner Cascadia and Western Star 5700XE trucks were being ordered with the DT12 AMT as opposed to a manual. Even traditionally conservative customers began to convert. As one industry veteran noted in 2018, “pretty much everything is going to be automatic [or AMT]” in the next few years. It’s clear that automated manual transmissions have evolved from a niche experiment into the new normal for heavy-duty truck drivelines.

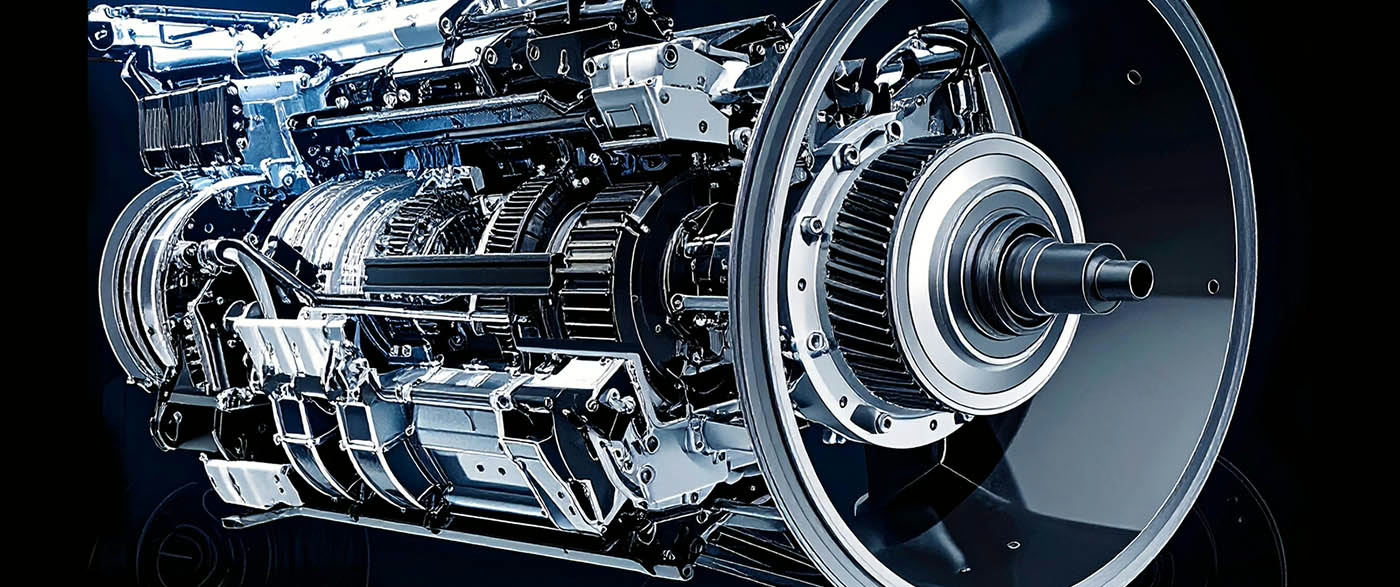

How an Automated Manual Transmission Works

From the outside, an AMT-equipped truck might look no different from an automatic: it has just two pedals (accelerator and brake) and perhaps a small shift selector or buttons. But internally, an AMT is fundamentally a manual transmission – typically a constant-mesh, non-synchromesh gearbox in heavy trucks – that is shifted by electro-mechanical or electro-hydraulic actuators under the command of an electronic control unit (ECU). There is still a clutch (or even two clutches in some advanced designs), but the clutch engagement is computer-controlled, not operated by the driver’s left foot. Here’s how an AMT functions and differs from other transmissions:

- Manual Gearbox with Automated Controls: The AMT retains the gears, shafts, and clutch of a traditional manual. However, gear selection and clutch actuation are performed by an electronic system (sensors, actuators, and a Transmission Control Unit) instead of by the driver. When it’s time to shift, the system automatically disengages the clutch, shifts to the target gear, and re-engages the clutch – all in fractions of a second and with coordination to match engine RPM for a smooth shift.

- No Torque Converter: Unlike a fully automatic transmission (which uses a fluid torque converter and planetary gearsets), an AMT maintains a direct mechanical link (via the clutch) between engine and wheels during engagement. Gear changes do momentarily interrupt torque (as the clutch opens), but the trade-off is a very efficient power transfer when the clutch is engaged – this contributes to fuel economy gains. By contrast, a conventional automatic uses planetary gears and wet clutches or bands with a torque converter, which can incur some efficiency loss.

- Electronically Synchronized Shifting: Heavy truck manual transmissions often do not have synchronizer rings (drivers traditionally “double clutch” and time shifts by matching revs). In an AMT, the computer performs that timing perfectly. It uses engine data, output shaft speed, and sometimes even incline sensors or GPS data to decide when and how fast to shift. Modern AMTs can skip-shift (jump over gears when appropriate) and rev-match precisely, something even skilled human drivers struggle to do consistently. Sensors monitor throttle position, road speed, engine RPM, and load, enabling the TCU to choose the optimal gear at any given moment.

- Automated Clutch Management: The clutch in an AMT is often a heavy-duty electronically-controlled unit (sometimes called “clutch-by-wire”). At startup or low speeds (where a human driver would slip the clutch), the AMT’s controller modulates clutch engagement for smooth launches. It also provides features like Hill Start Aid, which briefly holds the brakes or modulates the clutch on an incline to prevent rollback, so the driver can accelerate away without rolling. In crawling situations or precise maneuvering (backing into a dock), many AMTs offer a creep mode that simulates the feel of an automatic’s torque converter by applying just enough clutch to inch forward or backward without throttle.

- Integration with Engine and Brakes: A key to AMT performance is tight integration with the engine’s electronic controls. The transmission “talks” to the engine ECU – for example, during shifts the transmission may request the engine to momentarily reduce torque or adjust RPM. This coordination allows for faster, smoother shifts and protects the drivetrain. Modern AMTs also work with engine braking; they can downshift proactively to increase engine braking on downgrades, and even automatically engage the engine brake (Jake Brake) if needed to control speed. Many systems have predictive controls: e.g. predictive cruise control uses GPS and road gradient data to decide when to shift or coast for maximum fuel efficiency.

- Multiple Modes and Driver Input: While fully automatic in normal operation, most AMTs allow the driver some manual control. Drivers can typically switch to a manual mode or use paddle shifters/buttons to hold a gear or force an upshift/downshift when desired. This can be useful in certain conditions (e.g. holding a lower gear when climbing a grade or preventing an upshift in city traffic). However, even in manual mode, the AMT’s computer will usually prevent damaging shifts (it won’t let you downshift into over-speed or lug the engine excessively). Some manufacturers also provide selectable modes like Economy vs. Performance, adjusting shift timing (for fuel saving or more power).

- Advanced Features: Today’s AMTs come with a suite of smart features. For instance, Volvo’s I-Shift incorporates an Eco-Roll feature that can temporarily declutch on gentle downhill slopes to let the truck coast and save fuel. The Detroit DT12 has an eCoast function with similar effect, as well as Active Driveline Protection that avoids harsh shifts and driveline shocks. Many AMTs have built-in launch assist and urge-to-move features for ease in stop-and-go traffic. Because they are electronically controlled, they also enable over-the-air updates and remote diagnostics – for example, the DT12 is integrated with Detroit Connect telematics to report fault codes and suggest repair actions to fleet managers remotely. Self-protection logic is another benefit: an AMT won’t grind gears or miss shifts, and it can prevent engine over-revving or lugging by automatically shifting when limits are reached.

In summary, an AMT behaves much like a skilled human driver with an infinite attention span – always in the right gear, never forgetting to upshift or mis-timing a downshift. The result is consistent optimal performance, which pays dividends in fuel efficiency, reduced component wear, and easier driving. The next sections explore how major manufacturers have developed and implemented AMTs, and how these transmissions have evolved into the high-tech driveline components we see today.

Eaton’s Journey: from Fuller Manuals to UltraShift Plus and Endurant

When it comes to North American heavy-duty transmissions, Eaton is a household name. Eaton’s Fuller Roadranger manual transmissions (the classic 9, 10, 13, and 18-speeds) were standard equipment in semis for decades. As the industry began shifting toward automation, Eaton leveraged its deep experience in manuals to develop some of the earliest AMTs for trucks. Eaton’s first commercial automated product, the Fuller AutoShift, emerged in the late 1990s and early 2000s. The AutoShift was essentially a Fuller 10-speed manual with electronic shift control – it still had a clutch pedal for starting and stopping, but would automatically shift gears once the truck was rolling. This three-pedal design proved the concept and improved driver convenience on the highway, though drivers still needed to use the clutch when coming to a stop.

The real breakthrough for Eaton came in 2005-2006 with the debut of the UltraShift series. The Eaton UltraShift was a true two-pedal AMT – no clutch pedal at all – with a fully automated clutch. It built upon the AutoShift’s electronics but now took over all aspects of launch and gear shifting. This was introduced around 2006 in North America, at roughly the same time Volvo’s I-Shift was making waves. Eaton continued to refine this technology, later releasing the UltraShift Plus with multiple variants tuned for different applications (line-haul, vocational, etc.). These transmissions gained a reputation for robustness, as they were based on Eaton’s battle-proven manual gearsets combined with refinements like hill-hold and creep modes to make them more driver-friendly.

A significant milestone for Eaton was its partnership with engine maker Cummins. In 2017, Eaton and Cummins formed a joint venture called Eaton Cummins Automated Transmission Technologies, pooling their expertise to develop the next generation of heavy-duty AMTs. The flagship product of this venture is the Eaton Cummins Endurant transmission – a 12-speed AMT that was launched at the North American Commercial Vehicle show in 2017. The Endurant represents the state-of-the-art from Eaton: it’s lightweight, efficient, and built for modern high-torque engines. Weighing only about 715 lbs, the Endurant is considerably lighter than some older transmissions, yet it’s rated for up to 1,850 lb-ft of torque to handle the biggest engines. Eaton designed it with fuel economy and durability in mind – for example, it has precision lubrication and a transmission fluid pressure sensor to protect itself, and an extended maintenance interval (up to 750,000 miles between oil changes in line-haul service).

The Endurant also brought feature upgrades to improve low-speed maneuverability and support engine downspeeding. It offers an excellent ratio spread including deep reduction gears for startability, which helps in situations like pulling heavy loads from a stop or creeping in traffic. To achieve this without making it overly complex, Eaton offers the Endurant in both direct-drive and overdrive configurations to suit different fleet preferences (direct-drive for efficiency at cruise, or overdrive for maximum versatility). By 2020, the Endurant HD (as it’s now called, to distinguish from new vocational versions) was being made available across all major truck OEM brands – not just those with Cummins engines. For example, you can spec an Endurant in Freightliner Cascadia, International LT, Kenworth T680, Peterbilt 579, Volvo VNL, etc., usually paired with Cummins diesel engines, but even some Freightliners with Detroit engines offered Endurant as an option. This cross-OEM acceptance shows the confidence the industry has in Eaton’s AMT technology.

From a company history perspective, Eaton’s progression to AMTs is a case of a legacy manufacturer successfully adapting to new technology. They took the know-how of millions of manual transmissions in service and layered on electronics to create reliable AMTs. Features like error-free, “guess-proof” shifting and longer clutch life became selling points. Eaton also supplies the clutch assemblies for its AMTs; for instance, the Endurant uses an Eaton-concentric pneumatic clutch actuator and Advantage Series clutch, and Eaton backs it with its own warranty separate from the transmission. In the aftermarket, Eaton offers remanufactured UltraShift and Endurant units, allowing fleets to purchase reman AMTs with like-new performance. (Eaton’s reman process, much like others, involves full disassembly, inspection, replacement of all wear parts, and dyno testing to ensure the rebuilt transmission meets original specs.) For a company whose bread-and-butter was manual gearboxes, Eaton’s successful transformation to building world-class AMTs (especially in partnership with Cummins) underscores a key theme: electronic integration of engine and transmission is now just as important as the metal gears and shafts.

Volvo’s I-Shift: Pioneering Automation and Continual Innovation

Volvo’s I-Shift deserves special mention not only because it was the first heavy-truck AMT to hit the market (2001), but also because it proved that automated shifts could conquer even the most demanding trucking tasks. The I-Shift is a 12-speed single-countershaft transmission (derived from a manual design but heavily modified for automation) that immediately delivered tangible benefits in fuel efficiency and driver ease. After overcoming early skepticism, the I-Shift became a runaway success for Volvo. By Volvo’s own data, a truck with I-Shift could often outperform even an expert driver in fuel economy, by always shifting at the optimal RPM and preventing “bad” driving habits. Additionally, it opened up trucking to a broader range of drivers – newer drivers who might struggle with a 13 or 18-speed manual could now be productive immediately, easing the driver shortage problem. Veteran drivers, too, found that not having to constantly shift gears reduced fatigue and stress on long hauls.

In North America, the I-Shift’s acceptance grew steadily after its 2007 introduction. By 2013 Volvo Trucks North America made I-Shift standard on all VN series highway tractors, a bold move that paid off in market differentiation. As of 2021, about 94% of Volvo’s new orders in NA are I-Shift AMTs (with the remainder being Allison automatics or a few manuals for special cases). It’s a similar story globally: Volvo reports over 1 million I-Shift transmissions have been put into service worldwide. Today, every Volvo FH and FM truck in Europe comes with I-Shift standard, and the take-rate in many markets is essentially 100%. Competing brands even had to scramble to catch up, which is a testament to how Volvo’s early bet on AMT technology gave it a competitive edge.

Technically, the I-Shift has continually evolved. While the core design remained a single-clutch AMT, Volvo engineers kept adding capabilities:

- In 2014, Volvo introduced the I-Shift Dual Clutch, becoming the first to put a dual-clutch transmission (DCT) in a heavy truck. This innovation, borrowed from high-performance sports cars, uses two clutches to pre-select the next gear, allowing seamless power delivery with no torque interruption during shifts. For drivers, this meant incredibly smooth acceleration – under load, the truck can shift without the typical momentary loss of drive, which is especially beneficial on hills or when accelerating with heavy cargo. The dual-clutch version is particularly popular in applications like tanker trucks or premium fleet operations where any performance gain is welcome.

- In 2016, Volvo launched I-Shift with Crawler Gears. This variant added one or two ultra-low gears (up to a 32:1 ratio in the extreme) to facilitate starting heavy loads in severe conditions. With crawler gears, a Volvo truck can start moving a 200+ ton load from a standstill, or creep at under 1 km/h – capabilities once reserved for torque-converter automatics or special gearboxes. This opened the door for AMTs to be used in vocational segments like construction, heavy-haul, and forestry, where very slow maneuvering or extra high torque at launch is needed. It’s notable that Volvo achieved a world record using a truck with crawler-gear I-Shift to pull 750 tonnes (with the help of their strongman marketing stunt) – a dramatic demonstration of the transmission’s strength.

- Volvo has also integrated the I-Shift with numerous digital tools. For instance, Volvo’s “I-See” predictive cruise control system works with the I-Shift to automatically shift and throttle based on upcoming terrain, further boosting fuel efficiency. The I-Shift is fully networked into Volvo’s telematics: over-the-air software updates can improve shift strategies or add features, and Volvo’s remote diagnostics can monitor the transmission’s health. The transmission control unit tracks clutch wear and will alert when a replacement is due – an example of how maintenance is smarter with AMTs.

From a driver’s perspective, I-Shift has been lauded for making the job easier. Long-time manual drivers often report that after getting used to an AMT, they feel less tired after a full day of driving because they’re not constantly working the clutch and gearstick. Fleet owners, on the other hand, appreciate that every driver, regardless of experience, achieves near-optimal fuel economy with I-Shift – the variance between a rookie and a veteran narrows when the computer is handling shifting. It’s also easier on the equipment: clutches on an I-Shift typically last longer than on manuals, because the computer avoids abusive shifting and engages the clutch precisely (reducing hotspots and wear).

Volvo’s success with I-Shift influenced the whole industry. Mack Trucks, which is part of the Volvo Group, introduced the Mack mDRIVE in 2010, which is essentially an I-Shift adapted to Mack engines and vocational tuning. By 2020, Mack was installing mDRIVE AMTs in the majority of its trucks, even in heavy construction models, and offering an mDRIVE HD for extra rugged duty. Other competitors like PACCAR (Kenworth/Peterbilt), who traditionally bought Eaton manuals, have since developed their own AMTs (in collaboration with suppliers) to remain competitive. But Volvo’s I-Shift stands as a seminal development – it proved that an automated manual could handle high gross weights, steep mountains, and stop-and-go city routes with equal finesse. Two decades on, I-Shift remains a benchmark, and its name is practically synonymous with heavy-truck AMTs in many drivers’ minds.

Detroit DT12: Daimler’s Integrated AMT Strategy

In the early 2010s, Daimler Trucks (parent of Freightliner and Western Star in North America, and Mercedes-Benz trucks in Europe) recognized that integrating an in-house AMT with their engines could yield big gains in efficiency. The result was the Detroit DT12 automated manual transmission, introduced to the North American market around 2013. Branded “Detroit” to match the Detroit Diesel engines, the DT12 was a 12-speed, two-pedal AMT designed specifically to work seamlessly with Detroit engines (like the DD13, DD15, DD16) in Freightliner Cascadia and Western Star models.

The DT12’s rollout was part of Daimler’s global “integrated powertrain” approach – they wanted the engine, transmission, and axles to function as a cohesive unit. Initially, the DT12 was available only with the Detroit DD15 engine in the Cascadia, but by 2014 versions were released for the smaller DD13 and larger DD16 as well. Production of the DT12 started in Germany (at the Gaggenau plant in the Black Forest) and later moved to Daimler’s Detroit facility in Redford, MI. By localizing production, DTNA could supply the North American market more quickly and even export if needed.

One of the DT12’s selling points was weight savings – it was about 120 lbs lighter than comparable transmissions at launch, thanks to aluminum housings and an efficient design. It also came packed with features aimed at improving fuel economy and driver convenience, including: eCoast, which allows the truck to safely coast in neutral on slight downhill grades to save fuel; Skip Shift, where the transmission can jump gears when accelerating under light load; Active Driveline Protection, which senses driveline torque spikes and prevents damage (for example by momentarily slipping the clutch if a downshift is harsh). The DT12 offers multiple drive modes (such as Economy, Performance, and Manual) that drivers or fleet managers can select to suit conditions. In Economy mode, shifts are tuned for maximum MPG; in Performance mode, it might downshift sooner and hold gears longer for better hill climbing or acceleration.

Because the DT12 is integrated with Detroit Diesel engines, it leverages features like communications with the engine brake and cruise control. Daimler’s engineers developed what they call “Intelligent Powertrain Management” – using GPS and mapping to anticipate terrain. For instance, when approaching a hill, the DT12 can downshift preemptively, or with predictive cruise control, it might avoid unnecessary shifts by knowing a descent is coming. This synergy can be felt in real-world results: in one test, a Freightliner Cascadia with a DD15 engine and DT12 AMT averaged 8.4 MPG over 7,300 miles, a strong result for a fully-loaded rig, highlighting how well the transmission keeps the engine in its sweet spot.

Drivers who have tested or adopted the DT12 generally praise its shifting quality. Early skeptics (often seasoned truckers who swore by manuals) have come around as the DT12 and similar AMTs “learned” driver preferences and improved their responsiveness. The DT12 is equipped with Daimler’s Virtual Technician remote diagnostic system from the factory, which means if the transmission throws a fault code, that info is sent to a Detroit customer support center and relayed to the fleet – often allowing for quick troubleshooting or scheduling a repair before a breakdown occurs. The transmission’s control unit is also fully integrated with Detroit’s maintenance software (DiagnosticLink), so technicians can plug into one interface to get engine and transmission data in one go.

The serviceability of the DT12 was another design focus. Detroit optimized it to be “more service-friendly than a manual” – for example, no periodic clutch linkage adjustments are needed (there is no linkage – it’s electronic), and the clutch itself is a self-adjusting design. The system even tracks clutch wear and will alert when it approaches end-of-life. For vocational users, Detroit later released the DT12-V (for vocational), with heavier-duty clutches and gears to handle continuous off-road use, and PTO (Power Take-Off) integration for things like dump beds or mixers.

The market response to the DT12 has been extremely positive. Within just a few years of launch, the majority of Freightliner’s highway trucks were being spec’d with DT12s. As noted earlier, by 2017 about 70% of Cascadias were ordered with a DT12, and by 2020 DTNA said over 90% of all their line-haul trucks were AMTs (mostly DT12). Today, a manual transmission in a Freightliner is a rarity – many dealers don’t even stock manual trucks for on-highway applications because demand has dwindled. The Detroit DT12, paired with Detroit’s own engines, has become the cornerstone of Freightliner’s “Integrated Detroit Powertrain” branding, promising fleets a seamlessly coordinated engine-transmission that maximizes performance and efficiency.

Benefits of AMTs for Fleets and Drivers

Why have automated manual transmissions swept the trucking industry so quickly? The benefits span fuel economy, maintenance costs, driver recruitment, and overall performance. Below, we summarize key advantages of AMTs in heavy-duty truck operation:

- Improved Fuel Efficiency: AMTs consistently shift at the optimal engine RPM, something even experienced drivers cannot do perfectly on every shift. By keeping the engine in the most fuel-efficient range and even enabling advanced strategies like downspeeding (running at lower RPM on highway), AMTs can significantly boost MPG. Fleet studies show that while a top-tier driver might match the computer, an average driver will get better fuel economy with an AMT. Features like Eco-Roll (coasting) and predictive shifting further cut fuel consumption. For instance, Detroit Diesel noted that the DT12’s programming can lower engine speed at cruise (reducing fuel use) and only shift when truly necessary. In aggregate, fleets have reported substantial fuel savings after switching to AMTs – a critical benefit when fuel is one of their highest expenses.

- Lower Driver Fatigue, Easier Training: Driving a truck with 10, 13, or 18 gears through traffic is an art – and a physical workout. AMTs eliminate the constant manual shifting and clutching, which reduces fatigue on long drives. New drivers can get up to speed much faster since they don’t have to master double-clutching or gear patterns. This is a big deal in an era of driver shortages; an AMT opens the job to candidates who might otherwise struggle with a manual. Seasoned drivers also appreciate being able to focus more on traffic and less on what gear they’re in. One safety instructor explained that having automatics/AMTs means “there is less for drivers to worry about when they don’t have to shift gears,” allowing them to pay more attention to the road. In short, AMTs reduce the cognitive and physical load on drivers, which can also improve safety.

- Consistency and Reduced Wear: Not every driver is gentle on equipment. Manual transmissions in the wrong hands can suffer from grinded gears, slipped clutches, and shock loads. AMTs, by contrast, execute every shift with precision and built-in protection. The computer won’t “money shift” (e.g. accidentally go into too low a gear) and will prevent lugging or over-revving the engine. This leads to longer clutch life and less driveline abuse on average. Eaton has noted that fleets using AMTs see longer clutch service life and fewer repairs because the shifting is “guess-proof” and always rev-matched. Additionally, features like Active Driveline Protection in many AMTs guard against shock torque, potentially extending the life of U-joints, differentials, and other driveline components. All of this can translate to maintenance savings.

- Enhanced Features for Performance: AMTs often come with built-in features that improve truck operation, which would either be impossible or add-on devices in a manual. For example, Hill Start Aid holds the truck on a grade so it doesn’t roll back when accelerating – a welcome feature for any driver who’s stopped on an incline. Creep Mode allows for controlled low-speed movement without riding the clutch. Engine overspeed protection will prevent downshifting if it would spin the engine too fast. Many AMTs also integrate with collision mitigation and adaptive cruise control systems – they can downshift and apply engine brake automatically when the radar detects slowing traffic ahead, something a human driver might not do in time. These integrations make for a smoother and safer driving experience overall, pushing trucking further into the realm of advanced automation.

- Driver Recruitment and Retention: Fleets have found that offering trucks with automatics/AMTs helps attract a wider pool of drivers and even retain veteran drivers whose knees might be tired of clutching. In the past, some experienced truckers looked down on automatics, but that attitude is fading as the technology proved itself. Now, many drivers request automated transmissions. One large carrier noted that nearly 90% of the trucks it buys are automated because it allows them to recruit drivers who never learned on a manual, and even the old-school drivers are converting when they see the benefits. Having AMTs can thus be a competitive edge for fleets dealing with the chronic driver shortage.

It’s worth noting that manual transmissions are not completely dead – some operators still prefer them for simplicity or specific extreme-duty uses, and a subset of experienced drivers simply “like to shift”. However, as AMTs have addressed prior limitations (for example, by adding ultra-low crawler gears for heavy loads and improving hill-hold for construction use), there are fewer and fewer reasons to stick with a manual. The trend is clear: automated manuals now offer equal or better capability for almost all on-highway and many off-highway scenarios, with significant economic and operational upsides.

Remanufactured AMTs and the Aftermarket

With AMTs now so prevalent, the aftermarket has evolved to support them through remanufacturing and rebuilding services. A remanufactured transmission is one that has been taken apart, inspected, and rebuilt to OEM specifications, usually with all new wear components, to provide like-new performance at a fraction of the cost of new. This is especially important for expensive components like heavy-duty transmissions.

All the major OEMs have reman programs. For instance, Detroit Diesel offers Reman DT12 transmissions, which are rebuilt with 100% genuine Detroit parts and the latest design updates, then dyno-tested to ensure they perform like new. Eaton likewise sells remanufactured Eaton UltraShift and Endurant AMTs through its distribution networks. Volvo has its Volvo Reman division, which remanufactures I-Shifts and other components. Independent transmission specialists (such as the sponsor of this website) also remanufacture popular AMTs. They source core units (often through core exchange programs), completely disassemble and clean every part, replace damaged or worn pieces, install new bearings, seals, clutches, etc., and then test the assembly. The result is a transmission that can be installed in a truck to give it a “second life.”

Using remanufactured AMTs is a smart choice for many fleets. It reduces downtime – many reman providers offer exchange units that are ready to ship, meaning a truck can get a replacement transmission quickly rather than waiting for a custom rebuild. It’s also cost-effective: a reman unit typically costs significantly less than a brand-new transmission, yet often carries a similar warranty (e.g. one year/unlimited miles is common). Quality reman units are tested with the same rigor as new ones (100% dyno testing, etc.), so reliability is on par. From an environmental standpoint, remanufacturing also conserves materials by reusing the hefty castings and housings of these transmissions, only replacing what’s necessary.

For heavy-duty truck owners, this means that whether you have an Eaton UltraShift, Eaton-Cummins Endurant, Volvo I-Shift, Mack mDrive, or Detroit DT12, you have options to purchase a remanufactured transmission when it’s time for overhaul. Remanufacturers ensure that any engineering updates (for example, improved synchros or software updates) are incorporated, so in some cases a reman unit might even be better than the original was when new. As an example, Detroit Diesel’s official reman DT12 transmissions are built with all the latest upgrades that have been introduced since the DT12’s initial production, effectively bringing older trucks up to current spec in terms of transmission performance. Eaton’s reman offerings similarly benefit from all their field experience – known failure points from early models are addressed in the reman process.

In summary, the rise of AMTs hasn’t complicated maintenance – it’s simply shifted it towards electrical and software expertise combined with traditional gear work. Dealerships and independent shops have invested in training technicians on these units. Many diagnostics can be done through laptop-based tools (reading fault codes, checking clutch wear, updating firmware), and when mechanical repair is needed, modular design often allows sections (like the mechatronic shift module or clutch) to be serviced without tearing down the entire transmission. Still, when a full overhaul is needed, remanufactured AMTs provide a reliable, cost-efficient solution to keep trucks on the road.

Looking Ahead

The automated manual transmission has undoubtedly reshaped the landscape of heavy-duty trucking. What began a few decades ago as experimental technology – viewed warily by old-school truckers – is now a proven, mature solution that delivers tangible benefits to both fleet owners and drivers. History has shown a clear trajectory: from Eaton and Meritor’s early automated attempts to Volvo’s trailblazing I-Shift, to the widespread adoption by every major truck OEM, AMTs have evolved rapidly. Technically, they blend the best of two worlds: the durability and direct drive of a manual, plus the intelligence and ease-of-use of modern automation. Companies like Eaton, Volvo, and Detroit Diesel have each put their stamp on AMT development, pushing innovations like dual-clutch shifting, integrated telematics, and ultralow gearing that have expanded the capabilities of these transmissions.

Today’s heavy-duty truck driveline is a high-tech affair – engines and transmissions communicate digitally to optimize every newton-meter of torque. And when those transmissions eventually wear out, the remanufacturing industry is there to rebuild them to work like new, underscoring that AMTs are now an ingrained part of the truck lifecycle. For industry professionals and mechanics, the rise of AMTs means adapting to new diagnostic tools and training, but it also means a chance to deliver more value – in fuel savings, uptime, and driver satisfaction – to trucking operations.

In a world focused on efficiency, safety, and overcoming labor shortages, the automated manual transmission has proven to be the right technology at the right time. It has taken the heavy-duty trucking world by storm, and it’s here to stay. Whether it’s an Eaton Cummins Endurant, a Volvo I-Shift, or a Detroit DT12, the message is the same: smart shifting is the future of trucking’s powertrain. And as we look ahead, with even more computerization and perhaps electric drivelines on the horizon, the story of the AMT illustrates how innovation can transform an industry – one gear shift at a time.

Contact us today at 1-800-621-3914 to learn more about our AMT units and services and Request a Quote.

Recent Knowledge Base Articles

Contact Us Today

Our Experts are available to answer your questions and help you with your needs.

We take pride in getting you your answers, parts, and assemblies fast.

| 800-621-3914 |