At the heart of our success is a dedicated team committed to delivering exceptional customer service, leveraging deep product knowledge to offer solutions that align with various budgets and operational needs. With a legacy built on experience, expertise, and an unwavering commitment to quality, General Truck Parts continues to drive the industry forward, ensuring that clients receive the parts and support necessary to keep their operations running smoothly. Learn more about our expertise in the articles below.

Fabco: A Legacy in Heavy-Duty Drivelines and Transfer Cases

Fabco Automotive Corporation is an iconic name in the commercial vehicle and specialty drivetrain industry, with roots stretching back to 1918 in Livermore, California. Originally focused on innovative drivetrain solutions such as flexible couplings and diesel engines in the early 20th century, Fabco would go on to build a reputation as a premier manufacturer of transfer cases, steer drive axles, power take-off units, and specialty drivelines for severe-duty trucks and off-highway vehicles. Fabco’s Drive for Innovation Early…

Continue Reading Fabco: A Legacy in Heavy-Duty Drivelines and Transfer Cases

The Universal Joint: The Connecting Link of the Heavy-Duty Truck Driveline

From the early days of mechanical engineering to today’s heavy-duty commercial trucks, the U-joint has been the link holding everything together. Its genius lies in its simplicity: a mechanical connection that allows power to flow smoothly between rotating shafts at different angles, maintaining motion even when alignment is imperfect or constantly changing.

Continue Reading The Universal Joint: The Connecting Link of the Heavy-Duty Truck Driveline

Understanding the Relationship Between the Clutch and Transmission in Heavy-Duty Truck Drivelines

The clutch and transmission are two of the most critical components in a heavy-duty truck’s driveline. Together, they manage the delivery of power from the engine to the driveshaft, converting combustion energy into usable torque that moves tens of thousands of pounds down the highway. Understanding how these systems interact—and how their design changes between manual, automated manual, and automatic transmissions—is key to diagnosing problems, performing maintenance, and choosing the right components for your…

Truck Repair & Service: Driveline Expertise You Can Trust

For over 50 years, General Truck Parts has been a trusted name in the heavy-duty truck industry, providing dependable driveline remanufacturing and reliable truck service built on a foundation of experience, precision, and pride. From complete drivetrain remanufacturing nationwide to full-service truck maintenance in Chicago, General Truck Parts has earned its reputation as the go-to partner for fleets, municipalities, and owner-operators across North America. A Legacy of Reliability and Expertise Since 1974 we have…

Continue Reading Truck Repair & Service: Driveline Expertise You Can Trust

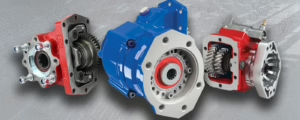

Comparing Muncie, Chelsea, and Bezares PTOs for Heavy-Duty Trucks

Power Take-Offs (PTOs) are critical components in heavy-duty highway and off-highway trucks, enabling engines to drive auxiliary equipment like dump bodies, cranes, blowers, and winches. Three prominent PTO manufacturers – Muncie Power Products, Parker Chelsea, and Bezares – each have long histories and extensive product lines serving the work truck industry. This article provides a technical comparison of their PTO offerings, including company backgrounds, typical industry usage, key product line differences, and an in-depth…

Continue Reading Comparing Muncie, Chelsea, and Bezares PTOs for Heavy-Duty Trucks

Transfer Cases: The Unsung Heroes of the Heavy-Duty Truck Driveline

When people think about truck drivetrain components, transmissions and differentials often take center stage. But for many heavy-duty truck drivelines, especially those in vocational and off-highway applications, there’s another critical piece of the puzzle: the transfer case. This underappreciated unit is responsible for distributing power where it’s needed most, ensuring trucks can handle the toughest terrain, heaviest loads, and most demanding work environments. In this article, we’ll explore what transfer cases do, why they…

Continue Reading Transfer Cases: The Unsung Heroes of the Heavy-Duty Truck Driveline

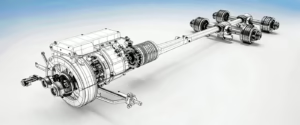

Heavy-Duty and Off-Highway Truck Transaxle Components: What You Need to Know

For heavy-duty trucks and off-highway vehicles, the drivetrain is the backbone of performance. At the heart of that drivetrain is the transaxle—a critical component that combines the functions of a transmission and drive axle into one integrated unit. In demanding applications such as construction, mining, and long-haul transport, a transaxle must deliver maximum torque, handle extreme loads, and operate reliably in rugged environments. That’s why understanding transaxle components and keeping them in peak condition…

Continue Reading Heavy-Duty and Off-Highway Truck Transaxle Components: What You Need to Know

What Is a PTO (Power Take-Off) and Why It Matters in Off-Highway Applications

In the world of off-highway equipment, where power, durability, and efficiency are non-negotiable, a Power Take-Off (PTO) system is a foundational component. Whether you’re running dump trucks, refuse vehicles, agricultural tractors, or utility service bodies, the right PTO can be the difference between peak productivity and operational setbacks. As a Muncie® Master Warehouse distributor, and a proud supplier of Chelsea® and Bezares® PTOs, we understand the critical role this equipment plays in your workflow.…

Continue Reading What Is a PTO (Power Take-Off) and Why It Matters in Off-Highway Applications

A Brief History of the Automated Manual Transmission (AMT) in Heavy Trucks

Automated Manual Transmissions (AMTs) are hybrid gearboxes that combine the internal mechanism of a traditional manual transmission with electronic controls to automate clutch engagement and gear shifting. In essence, an AMT uses a standard manual gearbox (with its multiple gear sets and clutches) but relieves the driver of having to operate the clutch pedal or shift lever. Instead, computer-controlled actuators handle all clutch and shift actions, giving the ease of an automatic while retaining the efficiency and robustness of a manual. This technology has become increasingly…

Continue Reading A Brief History of the Automated Manual Transmission (AMT) in Heavy Trucks

Remanufactured vs Rebuilt vs Used: What’s the Difference?

Choosing the Right Drivetrain Components for Your Heavy-Duty Truck When it comes to replacing critical drivetrain components—like transmissions, differentials, transfer cases, or power take-offs (PTOs)—heavy-duty truck owners and fleet managers face an important decision: should you go with a remanufactured, rebuilt, or used part? Each option has its place, but understanding the technical differences and long-term impact on performance, reliability, and total cost of ownership is crucial—especially when uptime and durability are non-negotiable in…

Continue Reading Remanufactured vs Rebuilt vs Used: What’s the Difference?

What is a Dynomometer?

How Precision Testing Powers Quality in Every Truck Part We Sell When it comes to truck parts and heavy-duty equipment, performance isn’t just a matter of horsepower — it’s about reliability, safety, and confidence mile after mile. That’s why companies committed to excellence like General Truck Parts go the extra mile with rigorous testing methods to ensure every component that leaves the shop is road-ready. At the heart of that testing process is a…

How to Choose the Right Remanufactured Truck Differential: Key Considerations for a Reliable Replacement

When a differential fails, truck owners and fleet managers are faced with a critical decision: repair, replace, or upgrade. For many, remanufactured differentials strike the perfect balance between cost, reliability, and availability—but choosing the right one requires more than just matching a part number. At General Truck Parts, we specialize in high-quality remanufactured drivetrain components, including differentials built to exacting OEM standards. This guide walks you through the key decision points to consider when…

The Legacy of Dana and Spicer: A Deep Dive Into Two Icons of the Trucking Industry

When it comes to the evolution of truck drivetrains, axles, and power transfer systems, few names are as influential as Dana® and Spicer®. For over a century, these brands have helped shape the modern trucking and automotive industries by pioneering some of the most durable and efficient components ever produced. Understanding their history not only showcases their legacy but also highlights why they remain trusted names in the heavy-duty parts world today. The Birth…

Continue Reading The Legacy of Dana and Spicer: A Deep Dive Into Two Icons of the Trucking Industry

The Remanufacturing Process: How We Bring Transmissions and Differentials Back to Life

At General Truck Parts, we understand the critical role that transmissions and differentials play in the performance and safety of heavy-duty vehicles. Our remanufacturing process is designed to restore these vital components to like-new condition, ensuring reliability and longevity for our customers. 1. Core Evaluation and Selection The journey begins with the careful selection of core components. Not all parts are suitable for remanufacturing; therefore, each core undergoes a thorough evaluation to assess its…

Differentials 101: What They Do and Why They Matter in Off-Highway Applications

When it comes to off-highway trucks, machinery, and heavy equipment, many intricate systems work together to ensure reliable performance in challenging environments. One of the most critical yet often overlooked components in a vehicle’s driveline is the differential. Whether you’re operating in the construction industry, mining, forestry, or waste management, the differential plays an essential role in delivering power to your truck’s wheels and enabling optimal handling on rough, uneven, or slippery terrain. In…

Continue Reading Differentials 101: What They Do and Why They Matter in Off-Highway Applications

Understanding the Anatomy of a Heavy-Duty Truck Transmission

A guide to what’s inside, how it works, and why it matters When it comes to the performance and reliability of heavy-duty trucks—on the highway or off the beaten path—the transmission is the unsung hero. Whether you’re running a long-haul fleet or managing off-highway equipment in harsh environments, understanding what’s inside a heavy-duty transmission can help you make better maintenance and purchasing decisions. What Is a Transmission? At its core, a transmission is responsible…

Continue Reading Understanding the Anatomy of a Heavy-Duty Truck Transmission

Proper Torque Settings for Installing or Maintaining the Front Carrier in Differential Repair

When performing differential repairs, especially with the front carrier of your truck’s axle, proper torque settings are crucial for ensuring the safety, performance, and longevity of the vehicle’s driveline. Differential systems play an essential role in distributing power to the wheels and enabling smooth operation. The front carrier, as a central part of this system, needs to be carefully installed and maintained to prevent costly breakdowns and ensure the vehicle operates at peak performance.…

Understanding the Minimum Bend Radius in Hydraulic Hoses

When it comes to maintaining and repairing hydraulic systems in trucks and heavy machinery, one key factor that cannot be overlooked is the minimum bend radius of hydraulic hoses. This seemingly simple specification plays a critical role in ensuring the longevity, performance, and safety of hydraulic systems. Whether you’re maintaining your fleet, repairing damaged equipment, or upgrading hydraulic components, understanding the minimum bend radius of hydraulic hoses is essential for optimal operation. In this…

Continue Reading Understanding the Minimum Bend Radius in Hydraulic Hoses

Contact Us Today

Our Experts are available to answer your questions and help you with your needs.

We take pride in getting you your answers, parts, and assemblies fast.

| 800-621-3914 |